"*" indicates required fields

Packaging in Harmony with Nature

Hoting Innovations recommends the SinterCell™ Automated Pulp Feeder System to optimize SinterCell™ 200 machine output and quality.

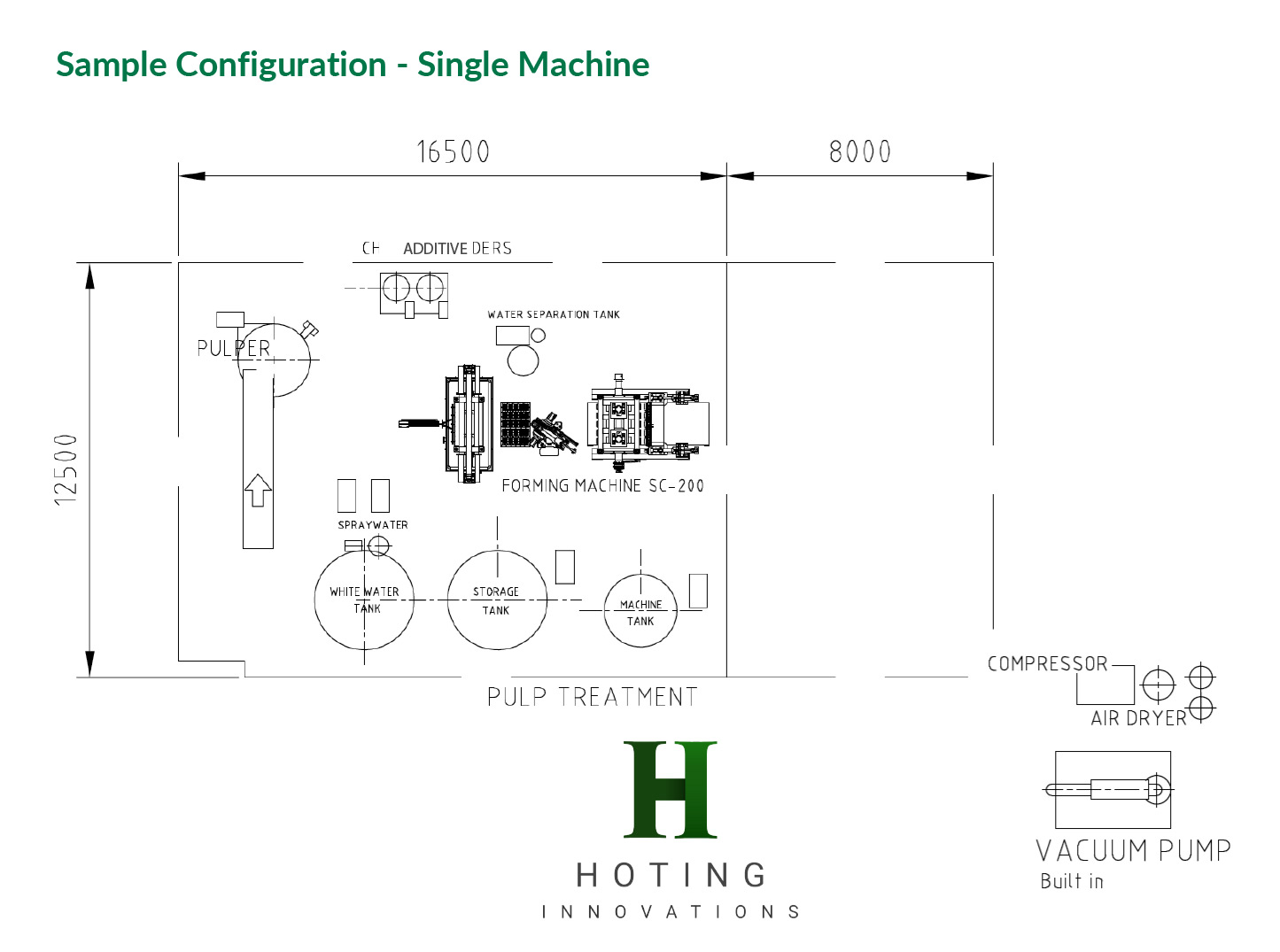

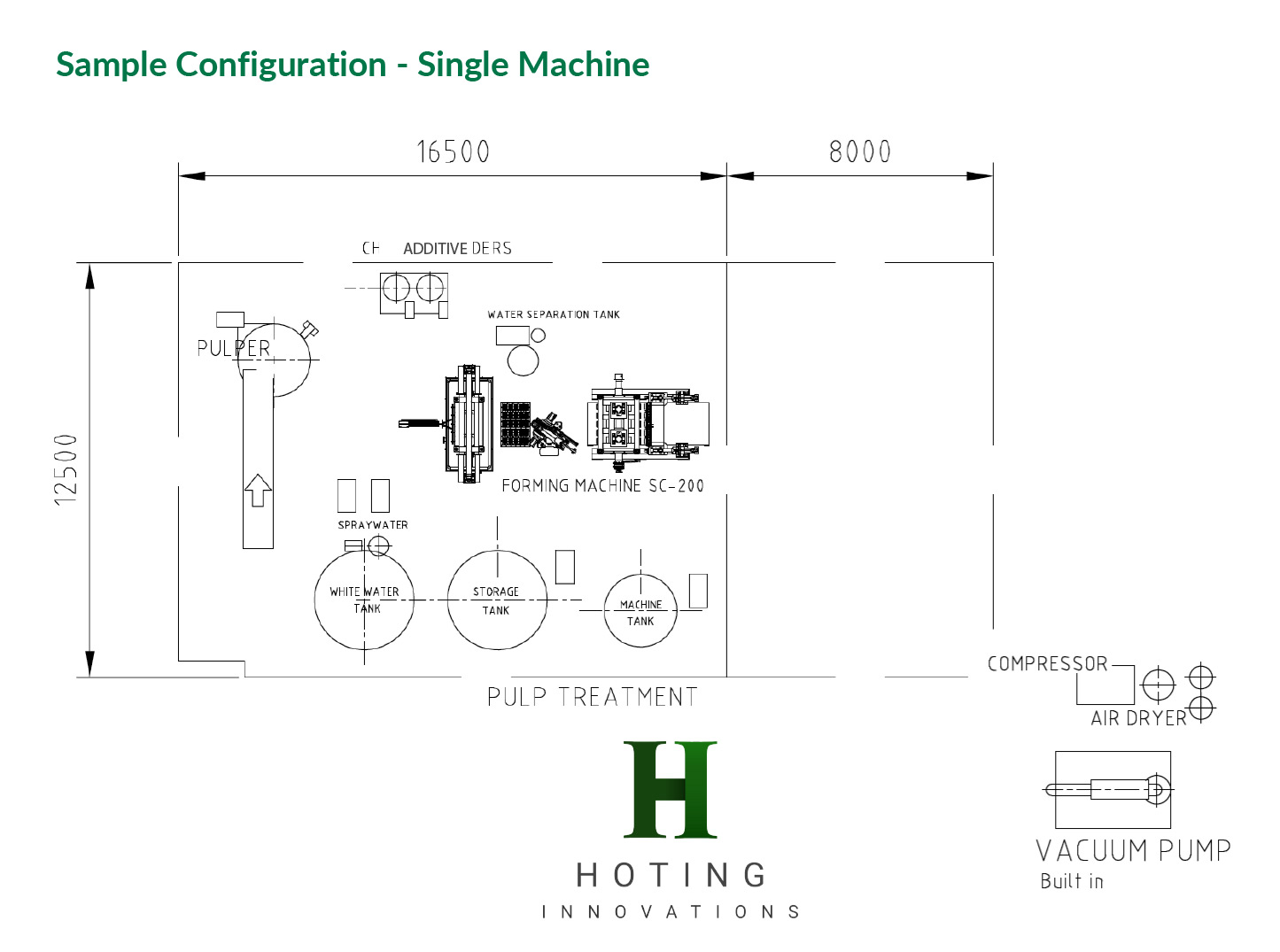

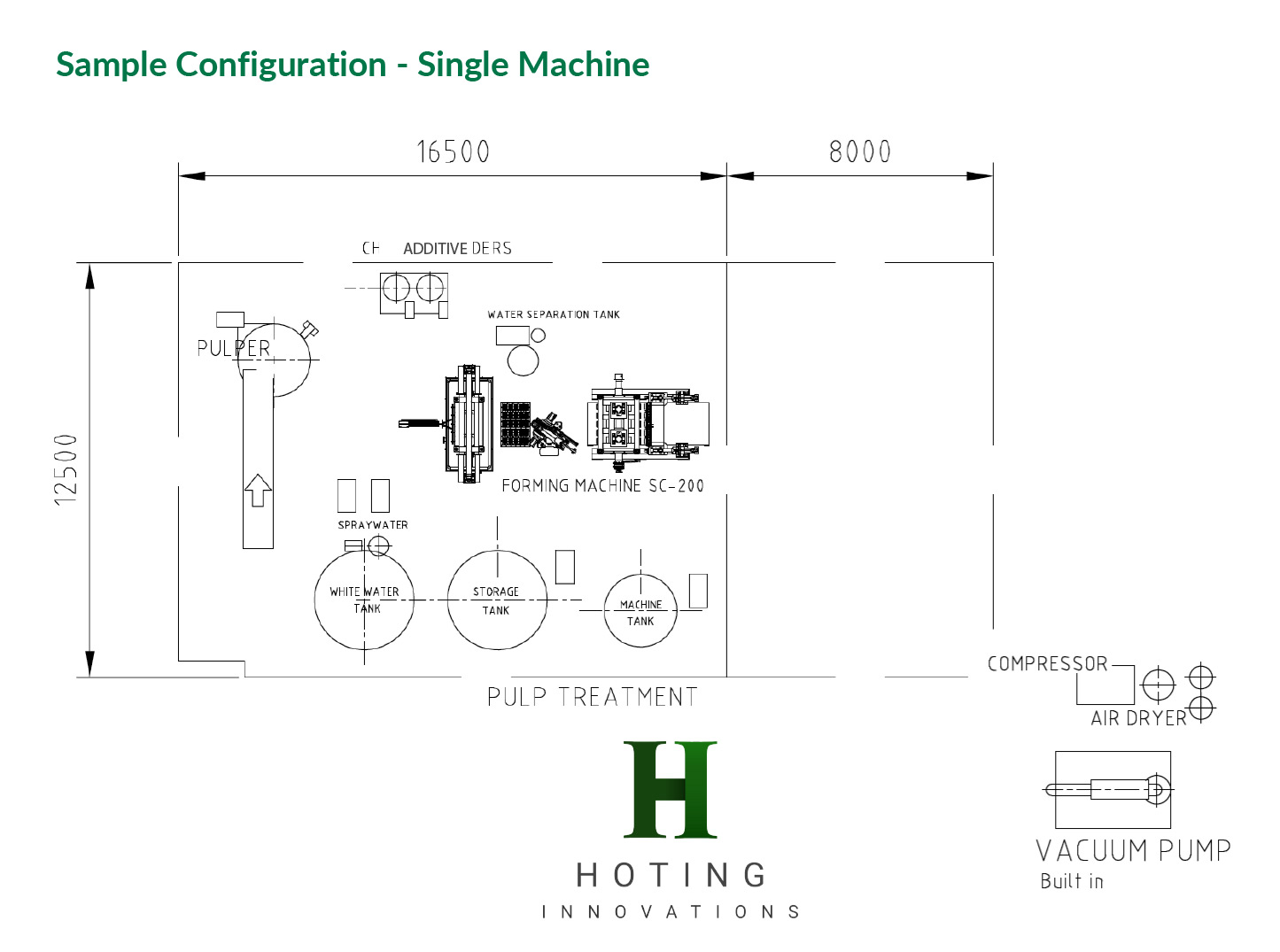

Hoting Innovations recommends the SinterCell™ Automated Pulp Feeder System to optimize SinterCell™ 200 machine output and quality. The standard Automated Pulp Feeder System is configured to support up to three SinterCell™ 200 production machines with each having a dedicated vacuum pump.

The automated control system takes the human element out of the pulp mixture formulation by continuously calibrating desired recipes with the right ratio of pulp to water and monitoring production output.

| Installed Power | • 140 kW: 80 kW feeder system and 60 kW per dedicated vacuum pump |

| Average Power Consumption¹ | • 86 kWh per 1000 kg of pulp processed |

| Slurry Concentrations | • Beginning: 4.0% • Final Dilution: 0.5% |

| Volume Capacity | • White Water Tank: 40 m3 • Storage Tank: 30 m3 • Machine Tank: 10 m3 (per machine) |

| Components | Description |

|---|---|

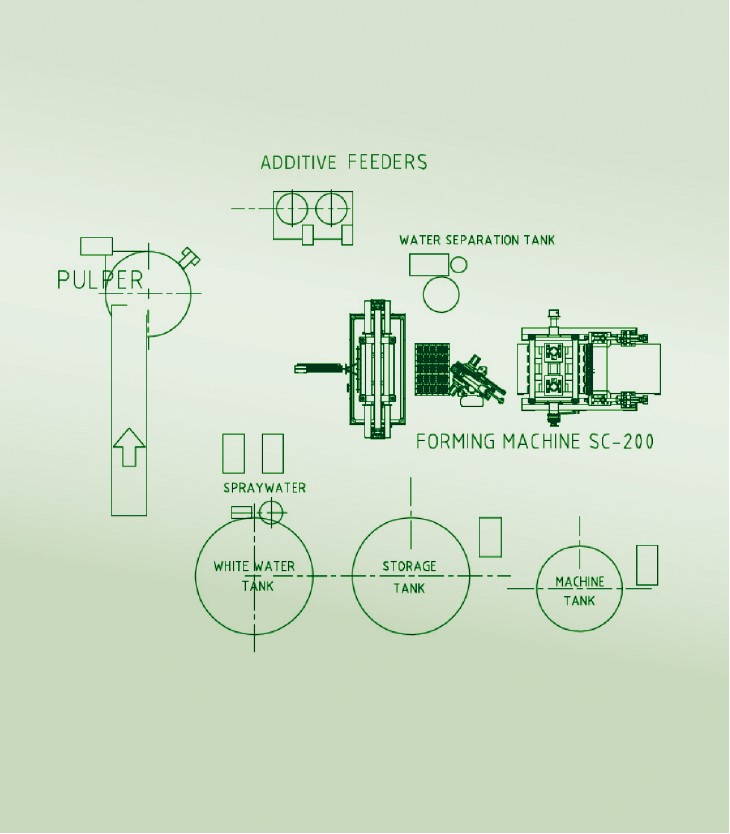

| Pulper | • Mechanical baled pulp dissolver with tank and pumping system. One • Pulper unit can serve up to three production machines. |

| Pulp Handling Unit | • The storage tank and white water tank for processing diluted pulp to a specified concentration. |

| Final Dilution Unit | • Two units; the machine tank that feeds the forming tank, and the water separation tank that pumps the drained water. |

| Additive Feeders | • The pump and flow meters used to feed relevant additives at various stages during pulp processing. |

| Recycled Water System (Closed-Loop) | • The white water tank and distribution pumping system for recycling white water back to the pulper. |

| Vacuum Pump | • One vacuum pump per SinterCell™ machine for the forming and transportation of products during operation. |

| Pipe Eonnection | • Pipe connections between SC-200 and the selected SC Pulp Feeding • System will be managed/supervised by Certified Hoting Technicians during installation |

Each automated pulp feeding system is configured to your facility footprint and SinterCell™ 200 machine layout. The Automated Pulp Feeder System doesn’t have any proximity requirements to the SinterCell™ 200 Production Machine, hence configuration options are only confined by the physical limitations of pipe connectivity.